Slag Drainage and Afterburners

Molten slag pools at the bottom of the furnace and helps maintain the high temperature inside the gasification chamber. Occasionally slag must be drained from the furnace. Some furnaces have drains positioned at a certain height, others use a tap system. Either way, slag drains away from the furnace and cools in a separate chamber.

Gas ventilation

The furnace also has a vent system to allow gasified components to pass into another part of the system (either an afterburner or a gas cleaning chamber).

Advertisement

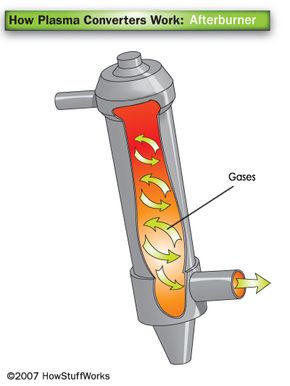

Afterburner

Gases can pass through a secondary chamber where natural gas flames combust any remaining organic material in the gases.

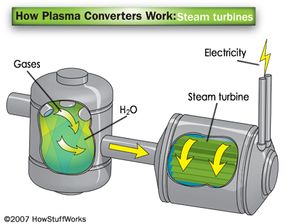

These extremely hot gases then pass through a Heat Recovery Steam Generator (HRSG) system, where they heat water to form steam. This steam then turns a steam turbine to create electricity.

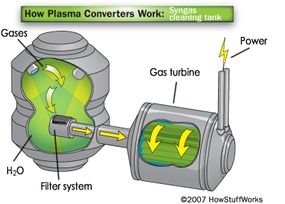

Syngas cleaning

Alternatively, the gases from the furnace enter a chamber where they are cooled and scrubbed, usually by water. The gases pass through a spray of water, which scrubs the gases of pollutants and particulates. A filter system containing a base filter neutralizes acid gases. The acids in the gases and the bases in the filter combine to form inert salts. The cooled and clean gases continue through the system, which in most cases involves a gas turbine connected to an electricity generator. Some systems also harness the heat from these gases to generate steam, similar to the afterburner method mentioned above.

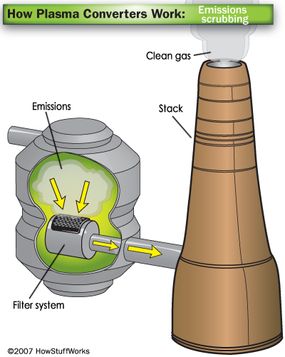

If the plant uses an afterburner, the remaining gases must be cleaned thoroughly to get rid of any hazardous material. Many designs include a dry scrubber system. In this system, powdered carbon is injected into the gases to strip away mercury, a poisonous element. Gases also pass through a fabric or bag filter to remove any other dangerous particulates, like lead. Once the gases have been cleaned they move to the stack, where they are released into the atmosphere.