A waterjet is a tool used in machine shops to cut metal parts with a (very) high-pressure stream of water. As amazing as it sounds, if you get water flowing fast enough it can actually cut metal.

Think of a waterjet as something with about 30 times the pressure of the power washer wand at your local car wash. Power washing at car washes is an everyday example of a dirt film being "cut" off the body, wheels and tires of an automobile.

Advertisement

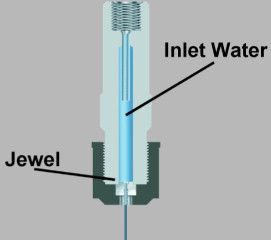

The key to cutting metal with water is to keep the spray coherent. Waterjets are able to cut because the spray is channeled through a very narrow jeweled nozzle at a very high pressure to keep the spray coherent. Unlike metal cutters, a waterjet never gets dull and it cannot overheat.

Low pressure waterjets were first used for mining gold in California in 1852. Steam and hot water jets were used in the early 1900s for cleaning. High pressure waterjets were used for mining in the 1960s, and about 10 years ago industry began using waterjets for cutting. Abrasive water jets (abrasivejets) were first used in industry in about 1980.

In the past, only one piece of metal could be cut at a time with a saw or other metal cutting mechanical process. It was time intensive and expensive. Computer-controlled waterjet and abrasivejet cutting are used today in industry to cut many soft and hard materials. The plain water-abrasive mixture leaves the nozzle at more than 900 mph. The latest machines can cut to within two thousandths of an inch, and have jet speeds around Mach 3.

Waterjets can cut:

- Marble

- Granite

- Stone

- Metal

- Plastic

- Wood

- Stainless steel

A water jet can cut a "sandwich" of different materials up to four inches thick. This odorless, dust-free and relatively heat-free process can also cut something as thin as five thousandths of an inch. The tiny jet stream permits the first cut to also be the final finished surface. This single cutting process saves material costs and machining costs. For example, the engineer merely gives a gear drawing to the cutting shop via a diskette or e-mail and gets the finished gear back.

Waterjets cut softer materials, while abrasive jets are used for harder materials. The actual cutting is often done under water to reduce splash and noise. Faster feed rates are used to prevent the jet from cutting all the way through.

The water pressure is typically between 20,000 and 55,000 pounds per square inch (PSI). The water is forced through a 0.010" to 0.015" in diameter orifice (hole) in a jewel.

A waterjet can remove the bark from a tree at a distance of 40 feet if one alters the chemistry of plain water by adding SUPER-WATER®, available from Berkeley Chemical Research. The SUPER-WATER® is a soluble polymeric chemical that acts like a series of molecular spinal columns or concrete reinforcement bars that tie the individual water molecules together in a more structured way to form a coherent jet. Imagine the potential for cutting down roadside weeds.

Advertisement