Practically all of us at one time have used a crayon or a marker pen. In this article we'll go on a tour of the Crayola Factory in Easton, Penn.

Binney & Smith, the maker of Crayola products, started out in the late 1800s making the color pigment for the paint used on the common red barns in rural America. Binney & Smith's carbon black was used by the Goodrich tire company to make automobile tires black and more durable. Originally, tires were white, the natural color of rubber.

Advertisement

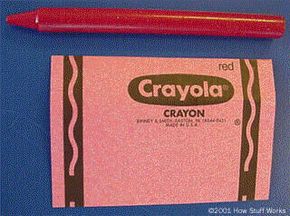

Crayons got their name from Edwin Binney's wife, Alice. She combined the words craie (French for chalk) with the first part of the word oleaginous (the oily paraffin wax) to make the word "crayola."

The two basic ingredients for a crayon are:

- Pigment

- Paraffin wax, stored in heated 17,000 gallon tanks

The mixture is heated until it melts into a liquid. Crayons melt at 105 degrees Fahrenheit (40 degrees Celsius). The mixture is heated to 190 F (82 C). The liquid is poured into a preheated mold full of hundreds of crayon-shaped holes. Cool water (55 F, 13 C) is used to cool the mold, allowing the crayon to be made in 3 to 9 minutes.

A single mold makes 1,200 crayons at a time, weighing a total of about 40 pounds. The operator uses hydraulic pressure to eject the crayons from the mold. Earlier mold designs used a hand crank to push up the crayons. The just-molded crayons are then manually quality checked for imperfections and inspected for broken tips. The excess wax from the mold and any rejected crayons are recycled to be re-melted. More than 120 crayon colors are possible.

Binney & Smith uses injection molding that allows them to make 2.4 to 6.4 million crayons in a day. See the new page to learn how they make Crayon labels.

Advertisement