Diesel engines are used in many types of vehicles, including locomotives. Diesel engines have a fuel efficiency 20 percent greater thermally than a gas engine. This means a 20 percent increase in fuel economy and therefore lower operating costs than those of a gas engine. Diesel engines also last longer than gas engines because they run at a much slower rpm (revolutions per minute) rate than gas engines do.

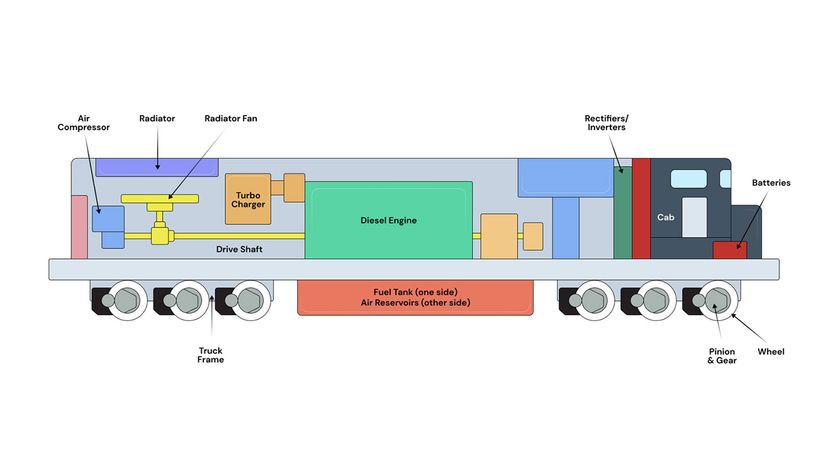

The hybrid diesel locomotive is an incredible display of power and ingenuity. It combines some great mechanical technology, including a huge, 12- to 16-cylinder, two-stroke diesel engine, with some heavy-duty electric motors and generators, throwing in a little bit of computer technology for good measure.

Advertisement

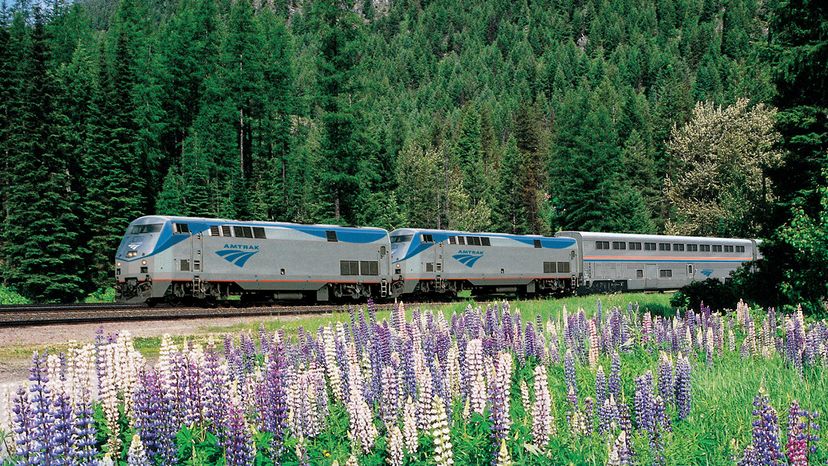

The locomotives weigh between 100 and 200 tons (91,000 and 181,000 kilograms) and are designed to tow passenger-train cars at speeds of up to 125 miles per hour (200 kph). Siemens' modern engines produce up to 4,200 horsepower, and the generator can turn this into almost 4,700 amps of electrical current. The drive motors use this electricity to generate around 60,000 lb-ft of torque. There is also a secondary diesel engine and generator to provide electrical power for the rest of the train. This generator is called the head-end power unit, producing between 500 and 700 kilowatts (kW) of electrical power.

This combination of diesel engine and electric generators and motors makes the locomotive a hybrid vehicle. In this article, we'll start by learning why locomotives are built this way and why they have steel wheels. Then we'll look at the layout and key components.

Advertisement