Key Takeaways

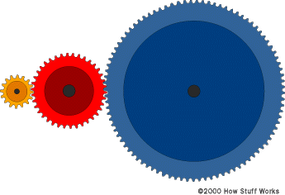

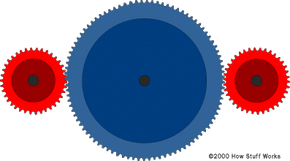

- Gear ratios are fundamental in understanding how gears work, with the ratio indicating how many times a gear has to turn for another gear to turn once; for instance, in a worm gear, a threaded shaft engaging the teeth on a gear can create a high gear ratio in a compact space.

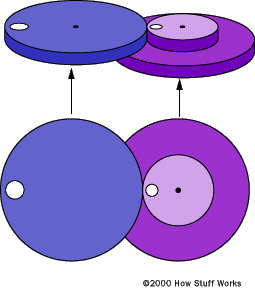

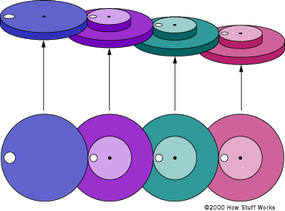

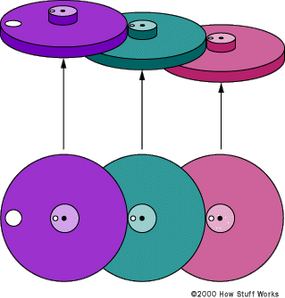

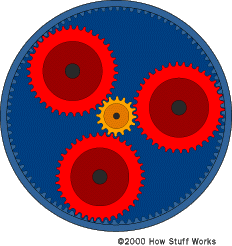

- Planetary gear systems are specialized gear trains that can produce different gear ratios depending on which gear is used as the input, output, or held stationary; they are rugged due to multiple gears engaging simultaneously and are commonly found in automatic transmissions.

- The versatility of planetary gearsets allows for different gear ratios by rearranging the input, output, and stationary gears, with automatic transmissions utilizing this feature by using clutches and brake bands to change the stationary parts and alter inputs and outputs.

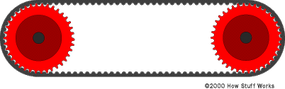

You see gears in just about everything that has spinning parts. Car engines and transmissions contain lots of gears. Wind-up, grandfather and pendulum clocks contain plenty of gears, especially if they have bells or chimes. You probably have a power meter on the side of your house, and if it has a see-through cover you can see that it contains 10 or 15 gears. Gears are everywhere where there are engines ormotors producing rotational motion.

Advertisement

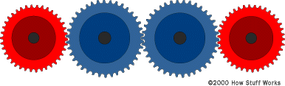

In this edition of HowStuffWorks, you will learn about gear ratios and gear trains so you'll understand what all of these different gears are doing. You might also want to read How Gears Work to find out more about different kinds of gears and their uses, or you can learn more about gear ratios by visiting our gear ratio chart.

Advertisement