Regular 2-D printers have become ubiquitous products in the modern age. Three-dimensional printers, on the other hand, are still able to turn some heads. Whether you're an architect or an artist, an educator or a product designer, a 3-D printer might be exactly what you're looking for.

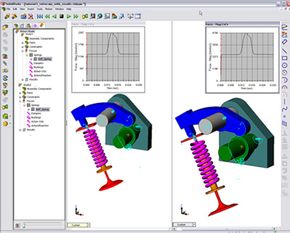

In some ways, the technology is similar to 2-D printing because it uses software to break down 3-D models into 2-D layers -- or cross sections -- of the desired prototype. There are a variety of methods to accomplish 3-D printing, but it's generally done in layers. For example, in one method, layers of fine powder are deposited onto the blossoming prototype, followed in turn by a layer of liquid binder. Once an object has been printed, it can be coated with sealant to strengthen it. Also, many of the machine's components are similar to those in regular printers, but that's where the technologies diverge.

For one thing, compared to 2-D printers, 3-D printers are slow. Sure, some are faster than others -- the Z Corporation makes one of the speedier ones on the market -- but even it only builds an inch or two an hour (depending on the size and shape of what is being printed). Their ZPrinter 450 lays down layers between .0035 and .0040 inches thick (.089 to .102 millimeters), and it can build prototypes that are 8 inches by 10 inches by 8 inches in size (20 by 25 by 20 centimeters). The Z Corporation has another model, the Spectrum Z510, which can build slightly larger prototypes with greater resolution and at about the same speed as the 450. The ZPrinter rings up at about $45,000 and the Spectrum Z510 at about $73,000 [source: Prototype Magazine, Prototype Magazine].

Despite potential drawbacks -- including the hefty price tag -- the possibilities of a 3-D ZPrinter are interesting to contemplate. You could print relief maps of the ocean floor, prototype products for pitch meetings, model human hearts for research or create architectural models to give construction workers a better visual picture of the design plans. And the best part -- it's all in color.

Different materials can be used in the printing process to create different characteristics in the finished products; they can be made more rubbery for example. Depending on the company, a range of techniques and materials can be utilized which impact the characteristics of the finished product. For instance, some make stronger prototypes, some offer more colorful results, others greater precision.

On the next page, let's take a closer look at the cutting-edge software that makes 3-D printing possible.