Key Takeaways

- Cold Heat soldering irons operate differently from traditional soldering irons by instantly heating up and cooling down, allowing for quicker use without the wait times associated with conventional tools.

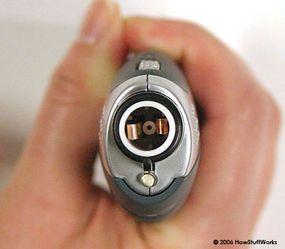

- This technology relies on electrical resistance, similar to resistance soldering tools, to quickly heat the solder through a current passed between two probes.

- Cold Heat tools simply employ established principles of resistance heating in a more affordable and accessible package.

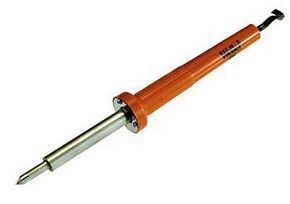

A Cold Heat soldering iron is a tool that seems to break the rules of soldering. As with other soldering irons, it melts solder -- an alloy that softens at a low temperature and hardens as it cools. Although solder (pronounced "soder") is commonly used to connect electronic components, you can also use it to make jewelry and stained glass. With the right type of solder, you can even repair metal containers, like pots and pans, or attach lengths of pipe to one another.

But while most soldering irons plug into a wall outlet, the Cold Heat tool uses batteries. Traditional irons get very hot and take a long time to cool off again, but the Cold Heat tool can heat up, melt some solder and cool off almost instantly. In one TV demonstration, someone uses the tool and then puts the tip on an inflated balloon -- the balloon doesn't pop.

Advertisement

To anyone who has burned a finger, damaged a table or melted a carrying case with a traditional soldering iron, the Cold Heat tool can seem pretty amazing. It's lightweight and portable, and it can cut down on the amount of time it takes to make small electronics repairs. On top of that, the Cold Heat tool doesn't come with the potential for serious injury or property damage. But reviewers -- professionals and average users -- either love the tool or hate it, and some people question whether it's really "new" at all.

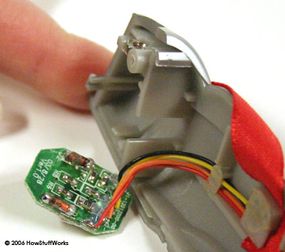

We wanted to know exactly how a Cold Heat tool works, so we took one apart. In this article, you'll learn Cold Heat's secrets, as well as what happened when we tried to use ours.

Advertisement