Key Takeaways

- The World Trade Center's builders utilized the slurry trench method to create a waterproof wall around the towers' basement, a technique learned from Italian engineering practices and previously seldom used in the U.S.

- The slurry wall, made from a mixture of bentonite clay and water that was later replaced with concrete, was designed to prevent water from the surrounding Hudson River from flooding the site, extending up to 80 feet (24 meters) underground and providing foundational support for the skyscrapers.

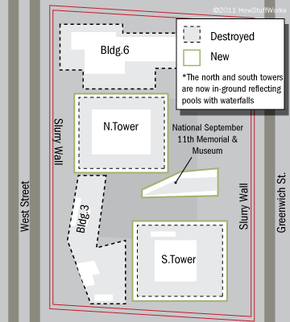

- Despite the devastation of September 11, 2001, the slurry wall remarkably withstood the collapse of the Twin Towers, later becoming a symbol of resilience and part of the National September 11 Memorial & Museum.

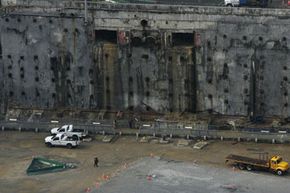

When terrorists crashed two airliners full of jet fuel into the World Trade Center (WTC) on Sept. 11, 2001, the resulting inferno, coupled with structural damage, caused what were then New York City's tallest skyscrapers to collapse and disintegrate into a mound of smoking rubble [source: NIST]. But amazingly, after the gray dust settled and engineers were able to probe the wreckage, they discovered that a critical part of the WTC complex had somehow survived. The slurry wall -- a 3-foot-thick (91 centimeters), below-ground, concrete structure surrounding the World Trade Center, designed to keep its basement levels from being flooded by the Hudson River -- remained in place [source: Nelson]. According to Arturo Ressi, an engineer who worked on construction of the barrier back in the mid-1960s, the survival of the slurry wall was a real blessing. In an interview with the 9/11 Memorial Museum, he explained that had that wall collapsed, the entire New York subway system might have flooded, and the loss of life could have been exponentially worse [source: 911memorial.org].

As workers at what came to be known as "Ground Zero" excavated the 1.2 million tons of steel and rubble that remained of the collapsed buildings, they worked around the slurry wall with great care, gingerly removing the debris that supported it when the buildings disappeared, and carefully reinforcing the wall with steel cables to prevent its collapse [source: Glanz and Lipton]. But even after the last of the rubble and tangled steel was cleared, Daniel Libeskind, the architect heading the redevelopment of the site, pushed to keep a portion of the original slurry wall in place. Though it no longer served its original practical function, the slurry wall had taken on greater importance as a memorial. In one sense, it was a tribute to American ingenuity -- to the architects, engineers and workers who accomplished the miracle of designing and constructing the tallest skyscrapers in New York City on the soft, porous surface of a landfill. It also stood as a remaining fragment of the tragedy, an iconic spot where Americans could mourn the lives that were lost. And finally, as part of the new complex -- arising like a phoenix from the ashes of the fallen towers -- the slurry wall was a testament to the determination and resilience of a nation. As Leibeskind put it, the slurry wall was a document "as eloquent as the Constitution itself" [source: Dunlap].

Advertisement

But before we get into the slurry wall's ultimate identity as a memorial, let's go back to its birth. How was this particular slurry wall conceived, and what important role was it to play for the Twin Towers?

Advertisement