Key Takeaways

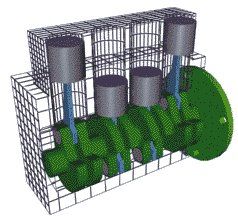

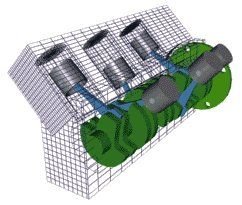

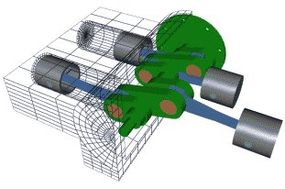

- Significantly different from multi-cylinder car engine design, radial engines arrange pistons in a circle around the crankshaft.

- This configuration typically features three to nine cylinders, with one piston's connecting rod fixed as the master rod and the others articulating around it.

- The unique design of the radial engine offers advantages in certain applications due to its compactness and efficiency.

If you have ever seen a World War II bomber like the B-25 or the B-17, or if you have ever seen or been on an old commercial airplane like a DC-3, then you are familiar with something called a radial engine. Many planes of the WWII era used very large, very powerful radial engines to drive their propellers.

In this article, you will learn how the radial engine works, what makes it different from other engine configurations and why it fits in so well with airplanes.

Advertisement

Advertisement