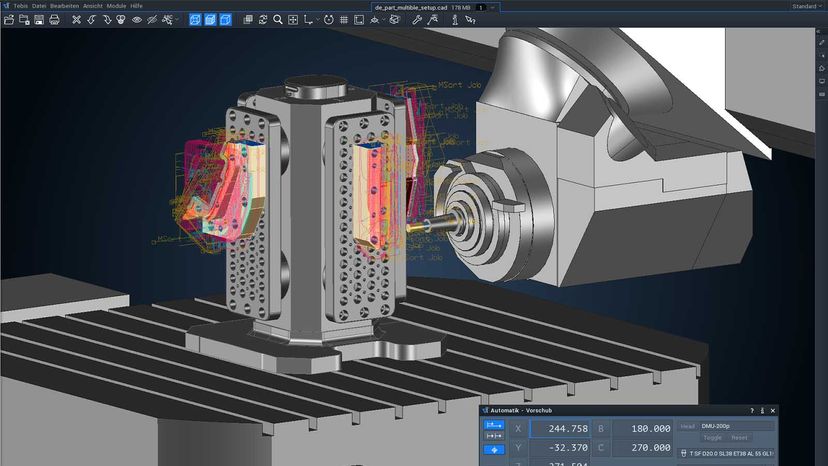

A computer numerical control machine (CNC) is a machining tool that forms stock material to a desired shape that will fulfill manufacturing directives and component requirements. CNC machines use pre-programmed software to control the movements of complex machinery, including grinders, lathes, mills and other cutting tools used to remove material.

These computer-aided manufacturing techniques can perform a wide range of complex and precise CNC machining tasks to create manufactured products and specifically designed parts for the automotive, defense and aerospace industries.

Advertisement

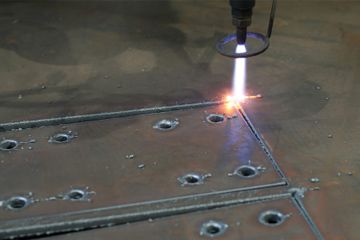

Although 3D printing and other additive manufacturing processes take center stage in the 21st-century production of components made with soft materials, most everyday items are still the result of highly automated subtractive machining techniques.

Plastic water bottles are produced from molds using the CNC die sinking technique, and individual drive system components of any car on the road are milled to accurate dimensions to allow all moving gears to fit together seamlessly for optimal mechanical performance.

"Chances are, nearly everything you touch in your day-to-day life was at some point touched by a machine tool," says University of Tennessee Knoxville engineering professor Tony Schmitz. "If you've ever traveled in an airplane — a Boeing 747, for example — over a million separate components were machined and then assembled to get that plane off the ground."

Advertisement