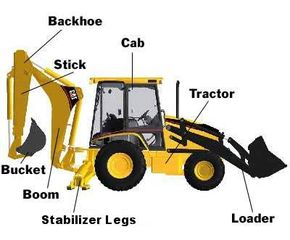

Backhoe loaders have a very unique appearance -- they have components sticking out every which way. It's obvious what a dump truck does just by looking at it; but what are the different appendages of a backhoe used for?

A backhoe loader is an interesting invention because it is actually three pieces of construction equipment combined into one unit. A backhoe loader is:

- A tractor

- A loader

- A backhoe

Each piece of equipment is suited to a particular sort of work. On a typical construction site, the backhoe operator usually uses all three components to get the job done.

The Tractor

The core structure of a backhoe loader is the tractor. Just like the tractors that farmers use in their fields, the backhoe tractor is designed to move easily over all kinds of rough terrain. It has a powerful, turbocharged diesel engine, large, rugged tires and a cab with basic steering controls (a steering wheel, brakes, etc.). Backhoe cabs are either completely enclosed or have an open canopy structure to give the operator protection.

The Loader

The loader is attached in the front and the backhoe is attached in the back. These two components serve very different functions.

The loader can do several different things. In many applications, you use it like a big, powerful dustpan or coffee scoop. You usually don't dig with it; you mostly use it to pick up and carry large amounts of loose material. It's also used to smooth things over like a butter knife, or to push dirt like a plow. The operator controls the loader while driving the tractor.

The Backhoe

The backhoe is the main tool of the backhoe loader. It's used to dig up hard, compact material, usually earth, or to lift heavy loads, such as a sewer box. It can lift this material and drop it in a pile to the side of the hole.

Basically, the backhoe is a big, extremely powerful version of your arm or finger. It has three segments:

- The boom

- The stick

- The bucket

This arrangement is very similar to your arm. Your arm has three segments -- your upper arm, forearm and hand.

The backhoe segments are connected by three joints, comparable to your wrist, elbow and shoulder. The backhoe moves in pretty much the same way as your arm. In a Caterpillar® backhoe, the boom is bent upward to make it easier to dig with obstacles in the way. This design also provides extra space for the bucket when the operator curls it in with a full load.

The backhoe can dig all sorts of holes, but is especially suited for digging ditches. To use the backhoe, the operator has to park the tractor and turn the seat around.

So what do the tractor, loader and backhoe have to do with each other? The tractor component is for moving the other two components from place to place, and the operator also maneuvers it when using the loader. The loader and backhoe components are a natural combination for all sorts of jobs. When you dig up a lot of dirt to make a ditch or any other sort of hole, you generally need a loader to either move the dirt out of the area or to fill the dirt back in once you've got the pipes, power lines, etc. in position. The most common application for a backhoe loader is this basic job -- digging a trench with the backhoe and then back-filling it with the loader.

The Stabilizer Legs

The other appendages you'll typically notice on a backhoe loader are the two stabilizer legs just behind the rear wheels. These legs are crucial to backhoe operation because they take the brunt of the weight when a backhoe is digging. Without the stabilizer legs, the weight of a heavy load or the downward force of digging into the ground would strain the wheels and tires, and the whole tractor would bounce constantly. The stabilizers keep the tractor steady, minimizing the jostling effect of digging with the backhoe. They also secure the tractor so that it won't slip into the ditch or hole.

The stabilizer legs have two types of "shoes," so that they can be planted securely on both dirt and pavement. The grouser shoe side digs into the dirt for a better grip, but would tear up the pavement if you were to use it on a road. For a good grip on asphalt, the operator simply flips the rubber-padded shoe into position.