The spinning jenny was invented by James Hargreaves, an English carpenter, in 1765. He patented his design five years later in 1770. Hargreaves developed the machine to address the limitations of traditional spinning methods, which required significant manual labor and were time consuming. The spinning jenny mechanized the spinning process, enabling the production of multiple threads at once.

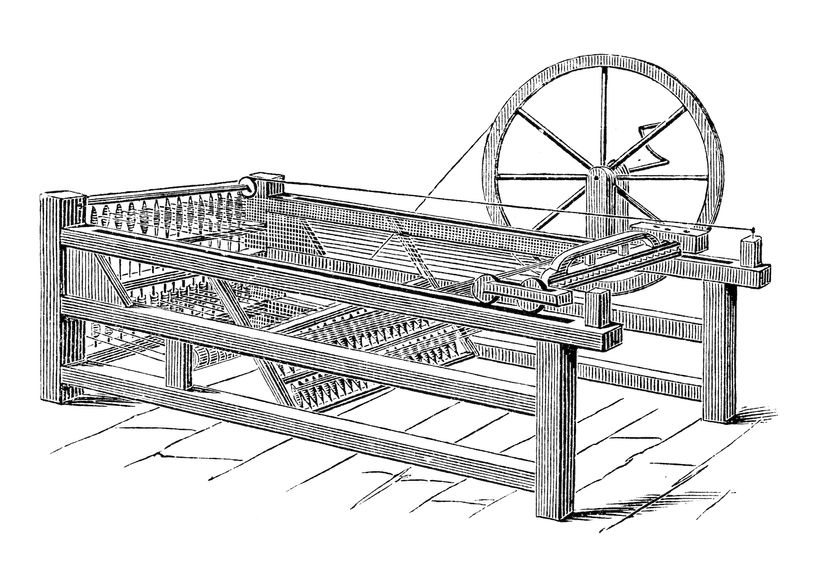

The machine consisted of a frame that typically held a set of eight spindles mounted on a spindle roll. Each spindle was equipped with a roving, which is a loose and twisted fiber bundle used for spinning.

The operator would manually rotate a large wheel, which, through a system of cogs and pulleys, would drive the rotation of the spindles. As the spindles rotated, the rovings were pulled and twisted into yarn. This innovation allowed for significantly more yarn production than traditional spinning methods.