The Loader

The business end of the skid steer loader is the loader arms. These arms and their associated hydraulics are designed to hold a variety of implements, not just buckets. The lifting capability of the arms is carefully matched with the rest of the machine so that the operator lifts the load, not the machine.

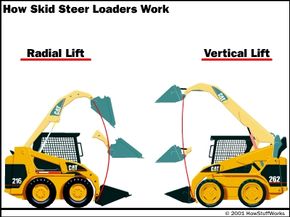

Most Caterpillar Skid Steer Loaders and Multi Terrain Loaders use a lift-arm design called radial lift. These lift arms are connected to the machine with a single pin on each side. The pins allow the bucket to follow an arc as it rises. As the bucket starts to rise, it first moves out, away from the machine. After it gets higher than the height of the mounting pin, it moves in closer to the machine.

Advertisement

The bucket sits close to the machine when it is in the down position to make the machine more stable and compact when moving loads around. As the bucket is raised, it moves away from the machine and then straight up. This gives the machine extra reach, making it easier to dump a load into the middle of a truck or place a pallet into a deep shelf, which is why Caterpillar recently released a skid steer loader with a new vertical-lift linkage. On a vertical-lift machine, the bucket starts in close -- the same as it does on a radial-lift machine. But by the time the bucket gets to about the operator's eye level, it has moved away from the machine by about 2 feet (0.6 m). From there, the bucket goes almost straight up until it reaches its maximum height of 128 inches (325 cm).

The new vertical-lift linkage uses two extra links on each side. The vertical lift linkage moves the loader arms forward as they rise.

Next, let's take a look at some of the tools that these loader arms can hold.