The basic idea behind any hydraulic system is very simple: Force that is applied at one point is transmitted to another point using an incompressible fluid. The fluid is almost always an oil of some sort. The force is almost always multiplied in the process.

For example if two pistons fit into two glass cylinders filled with oil and are connected to one another with an oil-filled pipe. If you apply a downward force to one piston, then the force is transmitted to the second piston through the oil in the pipe. Since oil is incompressible, the efficiency is very good -- almost all of the applied force appears at the second piston. The great thing about hydraulic systems is that the pipe connecting the two cylinders can be any length and shape, allowing it to snake through all sorts of things separating the two pistons. The pipe can also fork, so that one master cylinder can drive more than one slave cylinder if desired.

The neat thing about hydraulic systems is that it is very easy to add force multiplication (or division) to the system. If you have read How a Block and Tackle Works or How Gears Work, then you know that trading force for distance is very common in mechanical systems. In a hydraulic system, all you do is change the size of one piston and cylinder relative to the other.

Hydraulic multiplication. Lets say the piston on the right has a surface area nine times greater than the piston on the left. When force is applied to the left piston, it will move nine units for every one unit that the right piston moves, and the force is multiplied by nine on the right-hand piston.

To determine the multiplication factor, start by looking at the size of the pistons. Assume that the piston on the left is 2 inches in diameter (1-inch radius), while the piston on the right is 6 inches in diameter (3-inch radius). The area of the two pistons is Pi * r2. The area of the left piston is therefore 3.14, while the area of the piston on the right is 28.26. The piston on the right is 9 times larger than the piston on the left. What that means is that any force applied to the left-hand piston will appear 9 times greater on the right-hand piston. So if you apply a 100-pound downward force to the left piston, a 900-pound upward force will appear on the right. The only catch is that you will have to depress the left piston 9 inches to raise the right piston 1 inch.

The brakes in your car are a good example of a basic piston-driven hydraulic system. When you depress the brake pedal in your car, it is pushing on the piston in the brake's master cylinder. Four slave pistons, one at each wheel, actuate to press the brake pads against the brake rotor to stop the car. (Actually, in almost all cars on the road today two master cylinders are driving two slave cylinders each. That way if one of the master cylinders has a problem or springs a leak, you can still stop the car.)

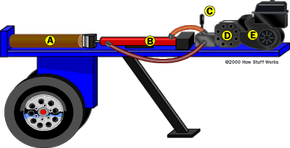

In most other hydraulic systems, hydraulic cylinders and pistons are connected through valves to a pump supplying high-pressure oil. You'll learn about these systems in the following sections.