Braze Filler Metals

In addition to the metals being joined, brazing has two important requirements -- a filler metal and a source of heat to melt the filler. We're going to look at each of these in greater detail, starting with the filler metal.

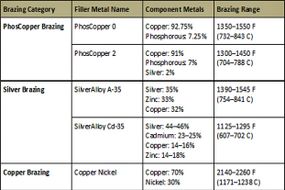

A brazing filler begins with one of several common primary metals: silver, aluminum, gold, copper, cobalt or nickel. These primary metals are then mixed, or alloyed, with other metals to improve or tweak their properties. For example, manganese acts as melting point suppressant, meaning it lowers the temperature at which the primary metal will melt. Chromium increases the strength of a brazed joint. And boron can help increase resistance to corrosion. The accompanying table shows a few common alloys used in brazing [source: Aufhauser Corporation].

Advertisement

Ultimately, metalworkers must balance a number of considerations when choosing a filler metal. Alloys behave differently than pure metals. The latter melt at a single temperature; they're a solid before this temperature and then, snap, they're a liquid. In contrast, alloys don't go directly from a solid to a liquid. Instead, they pass through a "mushy" stage during which they're both solid and liquid at the same time. A metalworker can use this to his advantage. If he's brazing a joint with a narrow clearance, he may choose a filler with a small brazing range, which results in a "lively" flow of filler metal in the gap. If he's brazing a joint with a wider clearance, he may choose a filler with a larger brazing range, which results in a "sluggish" flow that can adequately fill the gap. And, of course, he must be acutely aware of any hazards associated with the alloys used in the filler. Cadmium fumes, for example, are poisonous, so brazing with a cadmium filler must be done with adequate ventilation.

Finally, a metalworker must choose the form of the filler appropriate for the project. Some of this depends on how the filler will be applied. In some cases, he may place the filler in the joint before heating. Other times, he may manually feed the filler as he's heating. Either way, he has a wide selection [source:Sulzer Metco]:

- Powder -- The filler takes the form of dry, spherical particles. Each particle contains the elements making up the alloy in the proper proportion.

- Paste -- A paste combines alloy powders with a neutral binder to create a filler that can be extruded into a joint. Binders may be water or an organic compound and can affect the drying time of brazed joints.

- Tape -- Manufacturers use binders to attach thin ribbons of braze metal to an adhesive backing, which can be rolled up and shipped. They often cut the tape so its dimensions (width and thickness) conform to a metalworker's exact specifications.

- Foil -- Braze foil is a thin, but pure, sheet of metal alloy. It can be cut into pieces and shapes and stacked to produce filler of varying thickness.

- Rod -- Brazing rods come in diameters ranging from 0.3125 to 0.375 inches (0.7938 to 0.9525 centimeters). Like foil, rods contain just the elements making up the alloy, with no binders added.