Key Takeaways

- Building implosions are meticulously planned demolitions using explosives to ensure a structure collapses into its own footprint, minimizing damage to surrounding areas.

- Key preparations include weakening the building structurally, careful placement of explosives and calculating a safety perimeter to protect spectators and nearby properties.

- Despite the destructive nature of an implosion, it's a highly controlled and safe process.

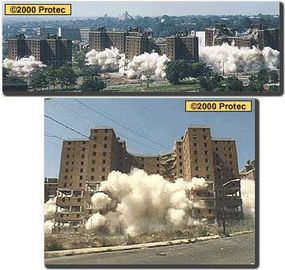

You can demolish a stone wall with a sledgehammer, and it's fairly easy to level a five-story building using excavators and wrecking balls. But when you need to bring down a massive structure, say a 20-story skyscraper, you have to haul out the big guns. Explosive demolition is the preferred method for safely and efficiently demolishing larger structures. When a building is surrounded by other buildings, it may be necessary to "implode" the building, that is, make it collapse down into its footprint.

In this article, we'll find out how demolition crews plan and execute these spectacular implosions. The violent blasts and billowing dust clouds may look chaotic, but a building implosion is actually one of the most precisely planned, delicately balanced engineering feats you'll ever see.

Advertisement

The Bigger They Come, the Harder They Fall

The basic idea of explosive demolition is quite simple: If you remove the support structure of a building at a certain point, the section of the building above that point will fall down on the part of the building below that point. If this upper section is heavy enough, it will collide with the lower part with sufficient force to cause significant damage. The explosives are just the trigger for the demolition. It's gravity that brings the building down.

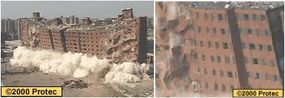

Demolition blasters load explosives on several different levels of the building so that the building structure falls down on itself at multiple points. When everything is planned and executed correctly, the total damage of the explosives and falling building material is sufficient to collapse the structure entirely, so cleanup crews are left with only a pile of rubble.

In order to demolish a building safely, blasters must map out each element of the implosion ahead of time. The first step is to examine architectural blueprints of the building, if they can be located, to determine how the building is put together. Next, the blaster crew tours the building (several times), jotting down notes about the support structure on each floor. Once they have gathered all the raw data they need, the blasters hammer out a plan of attack. Drawing from past experiences with similar buildings, they decide what explosives to use, where to position them in the building and how to time their detonations. In some cases, the blasters may develop 3-D computer models of the structure so they can test out their plan ahead of time in a virtual world.

The main challenge in bringing a building down is controlling which way it falls. Ideally, a blasting crew will be able to tumble the building over on one side, into a parking lot or other open area. This sort of blast is the easiest to execute, and it is generally the safest way to go. Tipping a building over is something like felling a tree. To topple the building to the north, the blasters detonate explosives on the north side of the building first, in the same way you would chop into a tree from the north side if you wanted it to fall in that direction. Blasters may also secure steel cables to support columns in the building, so that they are pulled a certain way as they crumble.

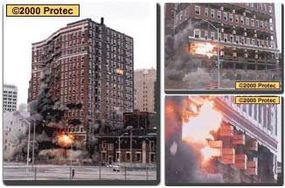

Sometimes, though, a building is surrounded by structures that must be preserved. In this case, the blasters proceed with a true implosion, demolishing the building so that it collapses straight down into its own footprint (the total area at the base of the building). This feat requires such skill that only a handful of demolition companies in the world will attempt it.

Blasters approach each project a little differently, but the basic idea is to think of the building as a collection of separate towers. The blasters set the explosives so that each "tower" falls toward the center of the building, in roughly the same way that they would set the explosives to topple a single structure to the side. When the explosives are detonated in the right order, the toppling towers crash against each other, and all of the rubble collects at the center of the building. Another option is to detonate the columns at the center of the building before the other columns so that the building's sides fall inward.

According to Brent Blanchard, an implosion expert with the demolition consulting firm Protec Documentation Services, virtually every building in the world is unique. And for any given building, there are any number of ways a blasting crew might bring it down. Blanchard notes the demolition of the Hayes Homes, a 10-building housing project in Newark, New Jersey, which was demolished in three separate phases over the course of three years. "A different blasting firm performed each phase," Blanchard says, "and although all of the buildings were identical, each blaster chose a slightly different type of explosive and loaded varying numbers of support columns. They even brought the buildings down in different mathematical sequences, with varying amounts of time factored in between each building's collapse."

Generally speaking, blasters will explode the major support columns on the lower floors first and then a few upper stories. In a 20-story building, for example, the blasters might blow the columns on the first and second floor, as well as the 12th and 15th floors. In most cases, blowing the support structures on the lower floors is sufficient for collapsing the building, but loading columns on upper floors helps break the building material into smaller pieces as it falls. This makes for easier cleanup following the blast.

Once the blasters have figured out how to set up an implosion, it's time to prepare the building. In the next section, we'll find out what's involved in pre-detonation prepping and see how blasters rig the explosives for a precisely timed demolition.

Advertisement