Vacuum and Cooling Systems

Vacuum Systems

Vacuums must be kept in accelerators for two reasons:

- to prevent sparking caused by microwaves in air, which would damage waveguide and accelerator structures

- to prevent loss of energy that would occur if the beam collided with air molecules

A combination of rotary pumps and cold traps are used to maintain the low vacuum (one-millionth of an atmosphere). Rotary pumps work like fans to remove air. Cold traps use liquid gases (usually nitrogen) to cool the surface of the trap. Any air or dust molecule will be attracted to the cold surface and removed from the tube. Cold traps must be kept cold or else they will release the collected dust and air molecules.

Advertisement

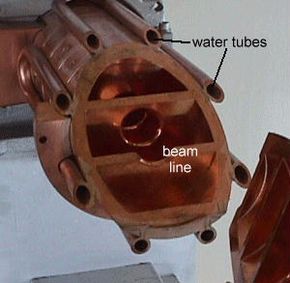

Cooling Systems

The electric currents passing through the copper tubing in the accelerator produce vast amounts of heat. This heat must be removed for two reasons:

- to prevent the copper tubing from melting - this would destroy the structure

- to prevent the copper tubing from expanding - this would break the vacuum seals

The SLAC linac has tubes of water to cool the copper tubing of the accelerator structure and the magnets. The cooling water is circulated to cooling towers above ground to remove the heat. Any superconducting magnets get cooled with liquid nitrogen or liquid helium. Because the linac is underground, there is less chance of seasonal heating and cooling.