Platinum is mined mainly in South Africa but is also sourced in Russia, Zimbabwe, the United States and Canada. Platinum mining involves several common types of mining methods, each suited to different geological conditions and deposit types.

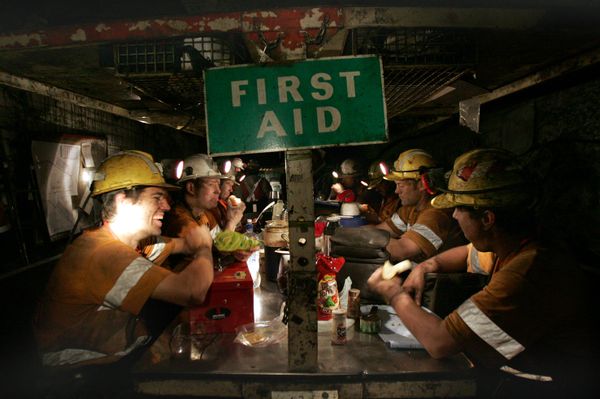

Underground Mining

There are a few types of undergrounding mining methods. In shaft mining, vertical shafts are excavated to access deep ore bodies. Miners use elevators and hoists to transport workers and materials to the underground mine.

In decline or adit mining, horizontal tunnels, known as declines or adits, are driven into the ore body from the side of a hill or mountain, allowing access to underground deposits without the need for a vertical shaft.

And finally, room and pillar mining is a method in which the ore body is divided into chambers or rooms, leaving pillars of ore to support the roof. This method is suitable for deposits with stable rock conditions.

Open-pit Mining

For this type of mining, large, deep pits are excavated to access ore bodies near the surface. This method is used for shallow deposits and can result in significant environmental disturbances due to the excavation of large areas.

Open-pit mining, while effective for shallow platinum deposits, can result in significant environmental disturbances due to the excavation of large areas, making it a less favored method in many mining operations today.

Alluvial Mining

Alluvial mining is the extraction of valuable minerals from sedimentary deposits, typically found in riverbeds, floodplains or areas where water has transported eroded materials.

It begins with natural erosion, where geological forces dislodge minerals from their sources. Water carries these materials, depositing them when its velocity decreases. Miners manually or mechanically extract these sediments, concentrating on valuable minerals like gold, diamonds or platinum.

Techniques such as panning and gravity separation are used to separate valuable minerals from less valuable components. After concentration, further processing, including refining or smelting, occurs to obtain the final product.

This method is often used for easily transportable minerals and varies based on the target mineral and scale of mining.

Heap Leaching

This process is used to extract valuable metals, often from low-grade ores. In this method, the ore is crushed and stacked into heaps or piles. Then, a leaching solution, typically containing chemicals like cyanide, is applied to the ore heap. Over time, the solution percolates through the heap, dissolving the target metals.

The dissolved metals are then collected and further processed to extract the desired metal, while the remaining waste material is typically disposed of in an environmentally responsible manner. Heap leach mining is a cost-effective technique for certain types of ore bodies.

In-situ Recovery (ISR)

In-situ recovery (ISR), also known as in-situ leaching or solution mining, is a mining method used for extracting valuable minerals from ore bodies without physically removing the ore. Instead, a leaching solution is injected directly into the ore deposit underground.

This solution dissolves the target minerals, and the resulting pregnant solution is pumped to the surface for processing. ISR is considered environmentally friendly because it minimizes surface disturbance and waste generation, making it a preferred method for certain types of deposits.