The basic idea behind body armor hasn't changed very much in the past few thousand years. First, armor stops weapons or projectiles from reaching a person's body. Second, it diffuses the weapon's energy so that the final impact causes less damage. While it's not effective in every situation, armor can generally help protect people from serious injury or death, especially against the right weaponry.

Over the years, people have had to develop stronger and more advanced armor to protect against increasingly sophisticated weapons. However, in spite of these improvements, modern body armor still has some of the same shortcomings as ancient forms of armor. Whether it's made from metal plates or layers of fabric, armor is often heavy and bulky. Many types are rigid, so they're impractical for use on arms, legs and necks. For this reason, medieval suits of plate armor had gaps and joints to allow people to move around, and the body armor used today often protects only the head and torso.

Advertisement

One of the newest types of body armor, though, is both flexible and lightweight. Oddly enough, this improvement comes from the addition of liquid to existing armor materials. While it's not entirely ready for combat, laboratory research suggests that liquid body armor has the potential to be a good replacement for or supplement to bulkier vests. Eventually, soldiers, police officers and others may be able to use it to protect their arms and legs.

The two primary types of liquid body armor currently in development both start with a foundation of DuPont Kevlar, commonly used in bulletproof vests. When a bullet or a piece of shrapnel hits a Kevlar vest, the layers of material spread the impact over a large surface area. The bullet also stretches the Kevlar fibers, expending energy and slowing down in the process. The concept is similar to what happens when a car air bag spreads the impact and slows the movement of a person's torso during a collision.

Although Kevlar is a fabric, Kevlar armor does not move or drape the way clothing does. It takes between 20 and 40 layers of Kevlar to stop a bullet, and this stack of layers is relatively stiff. It's also heavy -- a vest alone often weighs more than 10 pounds (4.5 kilograms), even without ceramic inserts for additional protection.

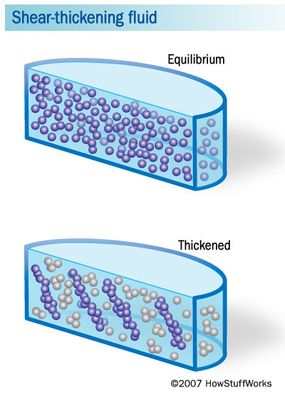

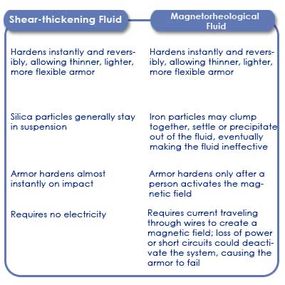

Two different fluids, however, can allow Kevlar armor to use far fewer layers, making it lighter and more flexible. Both of them have one thing in common -- they react strongly in response to a stimulus. Next, we'll look at what these liquids are made of and why they react the way they do.

Advertisement