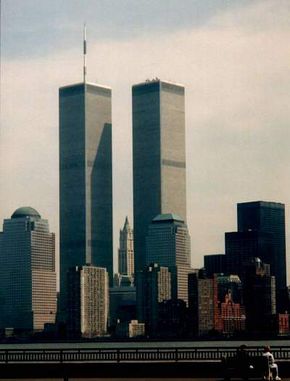

The "world's tallest building" title passes regularly from skyscraper to skyscraper. This is one of the most competitive contests in construction. Architects and engineers heartily embrace the challenges of building higher, and corporations and cities are always attracted to the glory of towering over the competition. The current champ is the Petronas Towers in Malaysia (see sidebar in previous section).

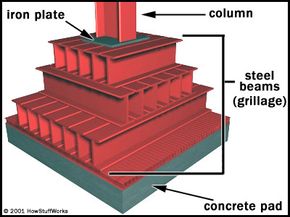

By all accounts, the skyscraper race is far from over. There are more than 50 proposed buildings that would break the current record. Some of the more conservative structures are already in construction. But the more ambitious buildings in the group are only theoretical at this time. Are they possible? According to some engineering experts, the real limitation is money, not technology. Super tall buildings would require extremely sturdy materials and deep, fortified bases. Construction crews would need elaborate cranes and pumping systems to get materials and concrete up to the top levels. All told, putting one of these buildings up could easily cost tens of billions of dollars.

Additionally, there would be logistical problems with the elevators. To make the upper floors in a 200-story building easily accessible, you would need a large bank of elevators, which would take up a wide area in the center of the building. One easy solution to this problem is to arrange the elevators so they only go part way up the building. Passengers who want to go the top would take an elevator halfway, get off and then take another elevator the rest of the way.

Experts are divided about how high we can really go in the near future. Some say we could build a mile-high (5,280 ft, or 1,609 m) building with existing technology, while others say we would need to develop lighter, stronger materials, faster elevators and advanced sway dampers before these buildings were feasible. Speaking only hypothetically, most engineers won't impose an upper limit. Future technology advances could conceivably lead to sky-high cities, many experts say, housing a million people or more.

Whether we'll actually get there is another question. We might be compelled to build farther upward in the future, simply to conserve land. When you build upward, you can concentrate much more development into one area, instead of spreading out into untapped natural areas. Skyscraper cities would also be very convenient: More businesses can be clustered together in a city, reducing commuting time.

But the main force behind the skyscraper race might turn out to be basic vanity. Where monumental height once honored gods and kings, it now glorifies corporations and cities. These structures come from a very fundamental desire -- everybody wants to have the biggest building on the block. This drive has been a major factor in skyscraper development over the past 120 years, and it's a good bet it will continue to push buildings up in the centuries to come.