Truss Bridges: Beam Bridges With Braces

Travel around the world, and you'll encounter dozens of variations on your standard beam bridge. The key differences, however, all come down to the design, location and composition of the truss.

During the early Industrial Revolution, beam bridge construction in the United States was rapidly developing. Engineers gave many different truss designs a whirl in an attempt to perfect it. Their efforts weren't for naught. Wooden bridges were soon replaced by iron models or wood-and-iron combinations.

Advertisement

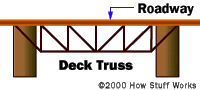

All these different truss patterns also factored into how beam bridges were being built. Some takes featured a through truss above the bridge, while others boasted a deck truss beneath the bridge.

A single beam spanning any distance undergoes compression and tension. The very top of the beam gets the most compression, and the very bottom of the beam experiences the most tension. The middle of the beam experiences very little compression or tension. This is why we have I-beams, which provide more material on the tops and bottoms of beams to better handle the forces of compression and tension.

And there's another reason why a truss is more rigid than a single beam: A truss has the ability to dissipate a load through the truss work. The design of a truss, which is usually a variant of a triangle, creates both a very rigid structure and one that transfers the load from a single point to a considerably wider area.

While truss bridges are largely a product of the Industrial Revolution, our next example, the arch, dates back much further in time. Grab your sword and sandals, because we're about to go Roman.