The baggage handling system at an airport plays a crucial role in keeping travelers happy. It also can make the difference in an airport's ability to attract or keep a major airline hub ("an airport that serves as a central connecting point through which many flights of a particular airline are routed" -- Webster's New World Dictionary).

A baggage-handling system has three main jobs:

Advertisement

- Move bags from the check-in area to the departure gate

- Move bags from one gate to another during transfers

- Move bags from the arrival gate to the baggage-claim area

The measure of a successful baggage-handling system is simple: Can the bags move from point to point as fast as the travelers can? If the bags move slower, you'll have frustrated travelers waiting for bags, or bags failing to make connecting flights on time. If the bags move too fast, you might have bags making connecting flights that passengers miss.

Each airport has its own requirements. For instance, the time allotted for a bag to make it from the check-in area to the gate is determined by how fast a passenger can make the same trip. In some airports, it might only be a short walk to the passenger terminal, while in others, passengers might have to take a train.

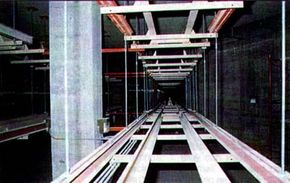

The Denver International Airport has a modern, automated baggage-handling system designed by BAE Automated Systems, Inc. (In June, 2003 G & T Conveyor Company, Inc. acquired BAE) United Airlines uses Terminal B at the Denver Airport as a hub, so this terminal has the most automation. This system incorporates some amazing technology to move bags from the check-in counter to the departure gate in an almost completely automated way:

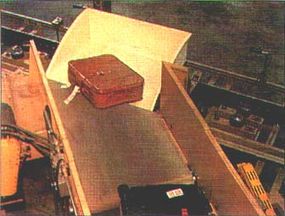

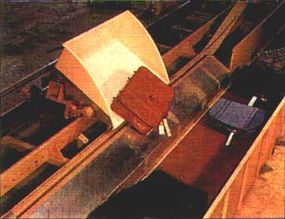

- Destination-coded vehicles (DCVs), unmanned carts propelled by linear induction motors mounted to the tracks, can load and unload bags without stopping.

- Automatic scanners scan the labels on the luggage.

- Conveyors equipped with junctions and sorting machines automatically route the bags to the gate.

In this article, we'll work our way through the baggage-handling system at Denver International, focusing on the United Airlines terminal. We'll start with an overview.