DCVs

The job of the destination-coded vehicle (DCV) is to move your bag quickly to an off-ramp at the gate. DCVs are used at the Denver airport because the distance from the main terminal to the passenger terminals is quite long, and passengers make the commute fairly quickly by train.

The DCV can travel up to five times faster than a conveyor -- almost 20 mph (32 kph).

Advertisement

What is a DCV?

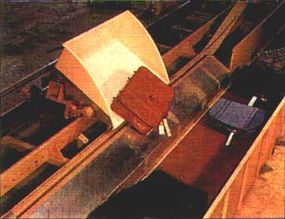

The DCV is a metal cart with wheels on the bottom and a plastic tub on top. Its only electronic device is a passive radio-frequency circuit that broadcasts a unique number identifying that particular car. This is similar to the circuit inside anti-shoplifting devices.

How is a DCV Propelled?

The DCV rides on a metal track, like a roller coaster. It is propelled by linear induction motors mounted to the track. Unlike most electric motors, a linear induction motor has no moving parts. It uses electromagnets to build two magnetic fields -- one on the track and one on the bottom of the DCV -- that are attracted to each other. The motor moves the magnetic field on the track, pulling the DCV along behind it at a high rate of speed. The main advantages of this system are its speed, efficiency, durability, precision and manageability.

A metal plate that hangs down from the bottom of the DCV rides between the linear induction motors. The motors are located about every 50 feet (15 m). Each time a DCV passes through one of the motors, it receives a boost from the motor that allows it to maintain speed while it coasts to the next motor on the track.

How Does a DCV Load?

The tub on the DCV is mounted on a pivot. Most of the time, the tub is tilted backward so that the bags cannot slide out (remember that DCVs can go around turns at almost 20 mph/32 kph). A linkage on the DCV locks the tub in this position.

When the DCV comes into a loading area, a bar on the track rises and engages a lever on the DCV. This lever tilts the tub into a flat position.

At the moment when an empty DCV is in front of the loading conveyor, your bag leaves the end of the conveyor belt and slides into the tub. This happens without the DCV stopping, so very precise timing is needed. The conveyors have optical pickups so they know exactly where your bag is and can make sure it hits the DCV perfectly each time.

Once your bag is loaded into the DCV, a rail on the track tilts the tub backward.

How Does a DCV Unload?

Unloading a DCV is a similar process. A mechanism on the track engages a lever on the DCV that causes the tub to tilt downward and dump your bag onto a section of conveyor that runs alongside the track.

The DCVs unload in one smooth motion as they move past the unload conveyer. After your bag has been deposited, a bar on the track raises the tub back into the tilted position.

By this point, your bag is very close to the plane. Let's take a look at how it completes its journey.