The concept of an elevator is incredibly simple -- it's just a compartment attached to a lifting system. Tie a piece of rope to a box, and you've got a basic elevator.

Of course, modern passenger and freight elevators are a lot more elaborate than this. They need advanced mechanical systems to handle the substantial weight of the elevator car and its cargo. Additionally, they need control mechanisms so passengers can operate the elevator, and they need safety devices to keep everything running smoothly.

There are two major elevator designs in common use today: hydraulic elevators and roped elevators.

Hydraulic elevator systems lift a car using a hydraulic ram, a fluid-driven piston mounted inside a cylinder.

The cylinder is connected to a fluid-pumping system (typically, hydraulic systems like this use oil, but other incompressible fluids would also work). The hydraulic system has three parts:

- A tank (the fluid reservoir)

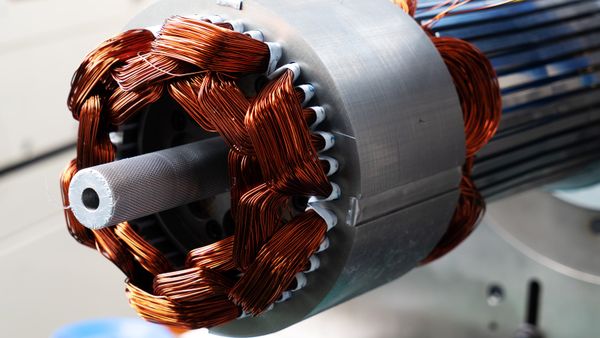

- A pump, powered by an electric motor

- A valve between the cylinder and the reservoir

The pump forces fluid from the tank into a pipe leading to the cylinder. When the valve is opened, the pressurized fluid will take the path of least resistance and return to the fluid reservoir. But when the valve is closed, the pressurized fluid has nowhere to go except into the cylinder. As the fluid collects in the cylinder, it pushes the piston up, lifting the elevator car.

When the car approaches the correct floor, the control system sends a signal to the electric motor to gradually shut off the pump. With the pump off, there is no more fluid flowing into the cylinder, but the fluid that is already in the cylinder cannot escape (it can't flow backward through the pump, and the valve is still closed). The piston rests on the fluid, and the car stays where it is.

To lower the car, the elevator control system sends a signal to the valve. The valve is operated electrically by a basic solenoid switch (check out How Electromagnets Work for information on solenoids). When the solenoid opens the valve, the fluid that has collected in the cylinder can flow out into the fluid reservoir. The weight of the car and the cargo pushes down on the piston, which drives the fluid into the reservoir. The car gradually descends. To stop the car at a lower floor, the control system closes the valve again.

This system is incredibly simple and highly effective, but it does have some drawbacks. In the next section, we'll look at the main disadvantages of using hydraulics.