Botany

Botany is a branch of biology focused on the study of plant life. Learn about the science of botany in this section.

Learn More

Trees are one of nature’s most incredible designs, providing oxygen, shelter and even maple syrup! From towering evergreens to small flowering plants, the diversity of trees is truly mind-blowing.

By Talon Homer

Also known as titan arum or Amorphophallus titanum, the corpse flower is known for its rare blooms. This unique plant sometimes takes seven to 10 years before reaching full bloom. When it finally does, plant enthusiasts rush to see this extraordinary occurrence up close.

By Ada Tseng

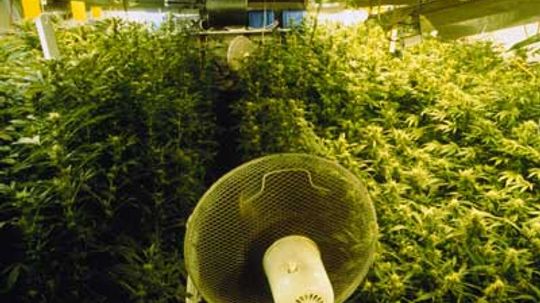

Understanding the major differences between indica vs. sativa strains of marijuana is important for cannabis use due to the different effects they incur on the human body and mind. Although both the indica strain and sativa strain can have medical benefits, they are used for different purposes.

By Karina Ryan

Advertisement

Time to get nutty! How much do you know about all of the different types of nuts out there? Take this quiz and find out!

By Alia Hoyt

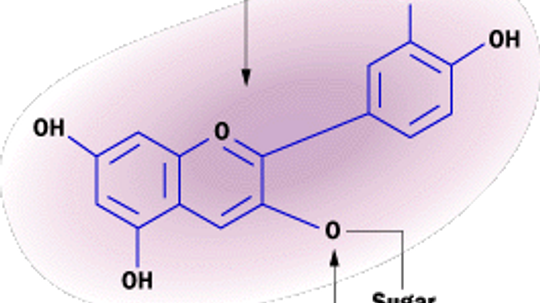

Researchers are studying the chemistry behind what makes cats go crazy for catnip. And whether or not the chemical compound could have medicinal benefits for treating diseases like cancer.

Nature uses color in lots of different ways. Find out why some types of cabbage are purple and what this means.

There is a good chance that if you go to the grocery store and buy a bunch of grapes that they will be of the seedless variety. If the grapes are seedless, how are they able to produce new grapes? Find out the answer to that question in this article.

Advertisement

Plants that eat other creatures? It sounds like a genetic experiment gone awry. But there's actually nothing unnatural about it; carnivorous plants have been around for millions of years.

For Jack and his beanstalk, the sky was the limit, but nature's giants hit a point at which they can't grow any taller. What prevents lofty trees like sequoias from soaring any higher?

Ten-tier wedding cakes, bagels slathered with cream cheese and slim, crusty baguettes -- we owe them all to wheat. What's the story behind this ancient, ubiquitous food crop?

By Robert Lamb

Have you ever suspected your neighbor was up to something illegal? He's always home and he gets midnight deliveries. Doesn't he have a job? Maybe he does, just not the kind you think.

By Robert Lamb

Advertisement

How can something as delicate and delicious as a cranberry thrive in something as filthy as a bog? Blame it on the durability of this most unusual and hardy plant.

By Russel Avery

They call kudzu the plant that ate the South for a reason. How did this leafy green legume make its way here all the way from Asia, and how has it managed to devour entire buildings?

Autumn rolls out its very own red carpet to make a fashionable arrival. So why do falling leaves change colors to vibrant hues of crimson, yellow and orange?

How does hemp work? What do rope and "organic clothes" and drugs have to do with each other?

Advertisement

Mexican jumping beans are small, brown beans that seem to have a life of their own as they jump and move around. But what is it that makes them jump?

If you've heard of frankincense and myrrh, it's probably because of the biblical account of Jesus' birth. But have you ever wondered what exactly it was the three wise men gifted?

Poison ivy is often very difficult to spot. But if you come into contact with it, you'll soon know by the itchy, blistery rash that forms on your skin. Learn how poison ivy causes that rash, and how to get rid of it.

How can the grass on the greens at a golf course be so perfect? What are they doing that's different from a normal lawn? Could my lawn look like this?

Advertisement

Pollen grains are, in essence, plant sperm. But how do the grains get where they need to go, and what's the advantage of trusting your genetic future to the winds?

Urushiol is the active chemical in poison ivy. Learn more about urushiol and how to properly remove poison ivy.

Many people think of cinnamon simply as a condiment that makes sweet treats taste even better, but the spice has had many, diverse uses over time. Could it have some medicinal properties, too?

By Diana Bocco

Like pretty well all living things, plants are equipped with natural defense mechanisms that help protect them from all the vicious animals out there that might want to eat them. In addition to stinging spikes and thorns, some plants are filled with deadly toxins that can make us violently ill or even kill us if [...] The post The 12 Deadliest Plants In The World appeared first on Goliath.

By Wes Walcott

Advertisement

Mangroves provide a habitat for wildlife such as fish, birds, deer and insects. They also stabilize shorelines, protect against storm surges and improve water quality. What's not to love?

Snake plants are attractive and virtually ironclad houseplants, almost impossible to kill, though some of the hype about them acting as air purifying filters has been overblown.