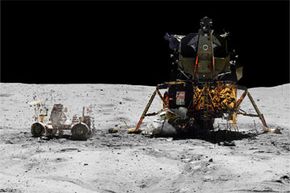

In 1972, the Apollo 16 mission returned to Earth with 731 rock and soil samples taken from the lunar central highlands, which they eventually sent to labs around the world. One of those labs was buried beneath Area 51, the top-secret military installation located in southern Nevada. There, a team of geologists and astrobiologists recovered spores of unknown origin from a rock's surface and stored the reproductive structures for further study.

The peculiar spores remained dormant until 1974, when they suddenly germinated, infecting dozens of lab workers and producing symptoms similar to those caused by the Ebola virus. The outbreak, known as the Crenshaw Episode after the first person to contract the mysterious illness, claimed seven lives until lab authorities could contain the microbes and prevent further infection.

Advertisement

Now the good news: We lied. The preceding story, at least the part about the Crenshaw Episode, is a complete fabrication. And the bad news: It's based on events that really could happen.

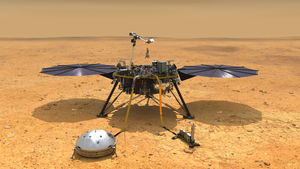

In fact, NASA created the Planetary Protection Office in the 1960s to consider scenarios just like these. Seriously? NASA really spends hard-earned taxpayer money to study extraterrestrial bugs? You bet. And it's not just because agency officials fret over a lunar or Martian microbe wiping out Earth's population. They're also worried about what our germs could do if they gained a toehold on another planet. A few transplanted bacteria might confound future searches for life or, worse, kill any indigenous organisms.

Yes, sir, humans have been mulling over this issue for decades. By the time John F. Kennedy delivered his "we choose to go to the moon" speech in 1962, scientists had already discussed the issue in September 1956, when the International Astronautical Federation convened its seventh congress in Rome.

Almost exactly a year later, the Soviet Union launched Sputnik, ushering in the space race and moving the concept of lunar and planetary contamination from a vague possibility to a sudden and frightening reality.

Advertisement