Military

Explore the weapons and combat systems used by the armed services. A broad range of topics in the Military Channel includes tanks, aircraft, biological warfare and stealth technologies.

Watch Your Six: Military Jet Pictures

McDonnell Douglas F-4 Phantom II

Lockheed P-38 Lightning

Does Army experience help your civilian career?

How NCO Professional Development Ribbons Work

How Army Reconnaissance Jobs Work

How Agent Orange Worked

How Biological and Chemical Warfare Works

How Mustard Gas Works

What Is the Strongest Military in the World?

5 Countries That Ditched Their Military Forces

Coast Guard Rescue Swimmers Risk All to Save Lives

Anatomy of an Underwater Explosion

Can You Really Outrun an Explosion?

How Blast-resistant Clothing Works

HowStuffWorks Illustrated: Two Legal Gun Modifications

Gun Pictures

What's the world's smallest gun?

Are robots replacing human soldiers?

Can drones replace fighter jets?

Do wars drive technological advancement?

Submarine Pictures

How the Zumwalt Class Destroyer Works

How Aircraft Carriers Work

How Military Video Conferencing Works

Why a Draft Would Weaken the U.S. Military

What Was the First War?

Top 5 Gadgets on the High-tech Soldier

Ghillie: Fishing Aid and Inspiration for Camo Suits

10 Insane Disguises That Actually Worked

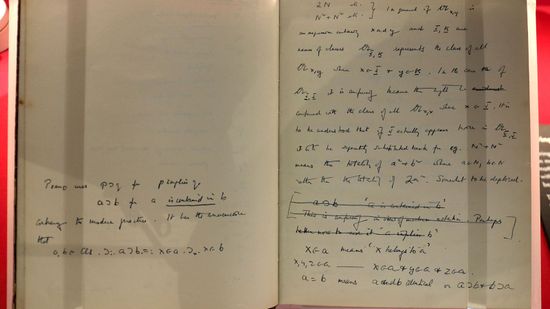

How Code Breakers Work

YOU Can Drive a Tank!

Is the army testing an invisible tank?

Centurion Main Battle Tank

Learn More

The word ghillie might conjure images of snipers or ghostly figures in thick brush. But its roots go back to Scotland and the River Spey, where ghillies originally served as guides for hunting and fishing.

Military power isn't distributed evenly across the globe. Some countries have huge armies, air forces and navies, while others have little more than some semi-professional militias.

By Zach Taras

An underwater explosion or UNDEX won't absorb the destruction like air does. Learn why an underwater explosion could harm you more than one on land.

By Robert Lamb

Advertisement

Tank Town USA is just one of a few places in the country where you don't have to be in the military to pay to drive a tank.

HowStuffWorks explains two ways that gun owners are modifying their semi-automatic weapons to fire like automatic ones.

Most experts agree that the all-volunteer military is what makes the U.S. armed forces the best in the world. Would that change if the draft was reinstated?

One U.S. Army leader says robots could account for a significant portion of American fighting forces in the next 20 years or so. Find out how machines are waging war now and how they may change the face of battle in the decades to come.

By Chris Opfer

Advertisement

"Die Hard" films' John McClane (not to mention a long line of other Hollywood action heroes) never met an explosion he couldn't outrun. In real life, it's not so easy to sprint away from a blast.

By Chris Opfer

As Benjamin Franklin once quipped: "There never was a good war or a bad peace." That's why these five countries have gotten out of the military business entirely.

Noncommissioned officers (NCOs) are the backbone of the U.S. Army, rising through the ranks to become leaders. But positions this demanding require extensive training, which the Army provides in the form of professional development courses.

Many believe the Army is the option people take when their career path hits a dead-end, or there's no money for college. But have you ever considered that joining the Army might actually open doors and help improve someone's career?

Advertisement

Wars and murders have much the same result -- by the end, someone will be dead. One is condoned, while the other is punished. Why is that? What makes the two so different from each another?

People have been fighting with one another longer than humans have recorded their history. But what was the first war?

Jets are one of the best tools that a military has at its disposal. They're fast, fierce and effective. From reconnaissance to target engagement, these aircraft are 10 sophisticated assets.

Submarines are built in a dry dock just like other seagoing vessels. Take an inside look at these fully submersible wonders of technology.

By Rick Mayda

Advertisement

Soldiers rely on all kinds of high-tech gadgets to help them get their jobs done. Some of them are specially designed for military use, while others are gizmos you might have in your pocket right now.

Guns come in all shapes and sizes. Put on your safety gear and take a look at this gallery of revolvers, Glocks, shotguns and even flamethrowers.

By Rick Mayda

Sure, G.I. Joe's accoutrements are tiny, but this itty bitty gun actually fires rounds. What is it, and why is it illegal to import into the United States?

By Josh Clark

While it says it doesn't participate in physical torture, the United States government has a manual of techniques to make prisoners talk. But are they torture?

By Josh Clark

Advertisement

Scientists are working on a cloaking method that would render tanks effectively invisible. New metamaterials may bend light, making the tank and its shadow indiscernible.

By Josh Clark

In its first few years, the McDonnell Douglas F-4 Phantom II set eight new aviation records, among them altitude (98,557 feet), speed (1,390 mph), and time to climb (9,000 feet in 34.5 seconds). Learn details about this popular and powerful aircraft.

The Lockheed P-38 Lightning was considered the most sophisticated aircraft Lockheed had ever built. The distinctive sight and sound of the P-38 would make it one of the best-known aircraft of the war. Learn more about the unique P-38 Lightning plane.

The Russian Yakovlev Yak-9 was faster and more maneuverable than many other planes. The Yak-9 model also featured more metal in the structure, so it was lighter and more maneuverable than earlier iterations. Read more specs for the Yak-9 airplane.

Advertisement

The Zumwalt is the military's class of next-generation destroyers. Find out how the Zumwalt class destroyer works and learn about Zumwalt technology.

As the newest fighter in the U.S. Air Force's aerial arsenal, the F/A-22 Raptor incorporates the latest stealth technology along with a mind-boggling array of weapons and computer systems. Learn about this dual-purpose fighter jet and attack aircraft and see what sets it apart from the F-15.